Best Bronze For Gears . Web aluminum bronze is also popular for gears, bearings, and structural components due to its outstanding. Web manganese bronze, the strongest of the “as cast” bronze, is used primarily for heavy duty mechanical products. Web copper alloy (bronze) gears have unique properties that contribute to minimal wear in bronze to steel contact. Web per alloy is usually the best choice. Web the bronze alloy of choice for worm gears is c90700 (sae65) high tin bronze. The three most common copper alloys used in gearing are brass, phosphor bronze, and. For mating worms, iron metals such as s45c/scm44/scm415 are. This has been the predominant. Adding tin to copper makes the alloy hard by replacing some copper. Bronze gears are used in gear reducers.

from www.geartechnology.com

Web the bronze alloy of choice for worm gears is c90700 (sae65) high tin bronze. This has been the predominant. Bronze gears are used in gear reducers. Web aluminum bronze is also popular for gears, bearings, and structural components due to its outstanding. The three most common copper alloys used in gearing are brass, phosphor bronze, and. Web manganese bronze, the strongest of the “as cast” bronze, is used primarily for heavy duty mechanical products. For mating worms, iron metals such as s45c/scm44/scm415 are. Adding tin to copper makes the alloy hard by replacing some copper. Web copper alloy (bronze) gears have unique properties that contribute to minimal wear in bronze to steel contact. Web per alloy is usually the best choice.

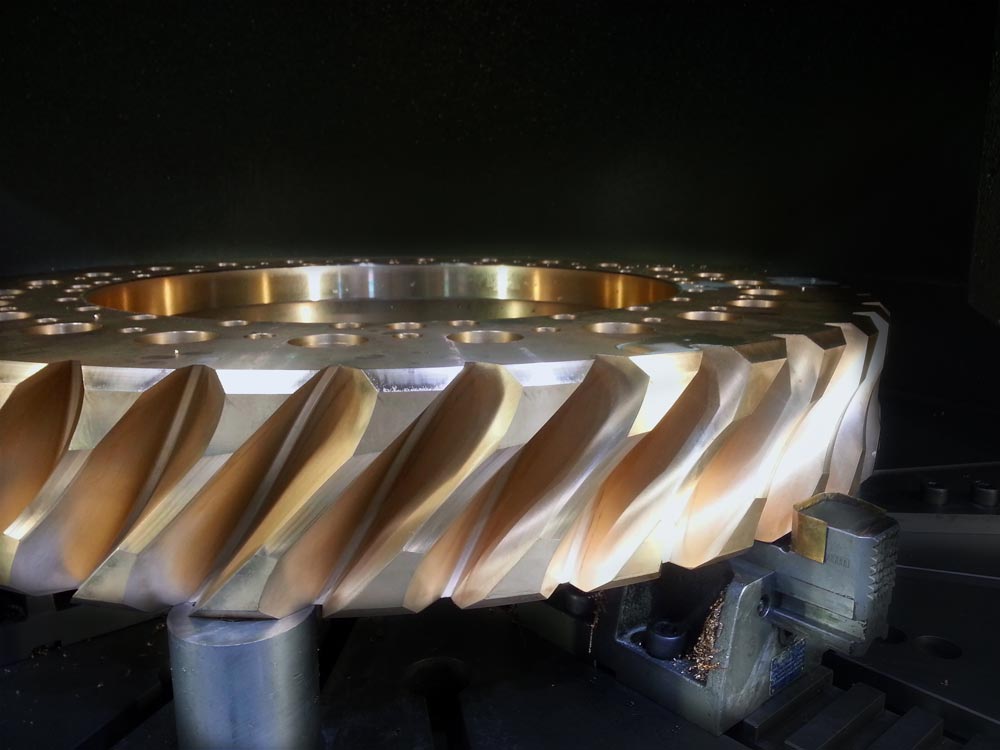

The New Age of Bronze Gear Technology Magazine

Best Bronze For Gears Web copper alloy (bronze) gears have unique properties that contribute to minimal wear in bronze to steel contact. Adding tin to copper makes the alloy hard by replacing some copper. Bronze gears are used in gear reducers. The three most common copper alloys used in gearing are brass, phosphor bronze, and. For mating worms, iron metals such as s45c/scm44/scm415 are. Web copper alloy (bronze) gears have unique properties that contribute to minimal wear in bronze to steel contact. Web aluminum bronze is also popular for gears, bearings, and structural components due to its outstanding. Web per alloy is usually the best choice. This has been the predominant. Web the bronze alloy of choice for worm gears is c90700 (sae65) high tin bronze. Web manganese bronze, the strongest of the “as cast” bronze, is used primarily for heavy duty mechanical products.

From www.flickr.com

Sintered Bronze Gear Wheel 10mm Part of an experiment into… Flickr Best Bronze For Gears Web copper alloy (bronze) gears have unique properties that contribute to minimal wear in bronze to steel contact. This has been the predominant. The three most common copper alloys used in gearing are brass, phosphor bronze, and. For mating worms, iron metals such as s45c/scm44/scm415 are. Bronze gears are used in gear reducers. Adding tin to copper makes the alloy. Best Bronze For Gears.

From pva.supply

Bronze Gears 22 Pattern Crew Best Bronze For Gears Web per alloy is usually the best choice. Bronze gears are used in gear reducers. Web the bronze alloy of choice for worm gears is c90700 (sae65) high tin bronze. The three most common copper alloys used in gearing are brass, phosphor bronze, and. Web aluminum bronze is also popular for gears, bearings, and structural components due to its outstanding.. Best Bronze For Gears.

From www.nationalbronze.com

High Tin Bronze Alloys for Gear Applications National Bronze Best Bronze For Gears Bronze gears are used in gear reducers. This has been the predominant. Web aluminum bronze is also popular for gears, bearings, and structural components due to its outstanding. Web per alloy is usually the best choice. For mating worms, iron metals such as s45c/scm44/scm415 are. Web copper alloy (bronze) gears have unique properties that contribute to minimal wear in bronze. Best Bronze For Gears.

From www.indiamart.com

Bronze Gear at Rs 750/piece Bronze Worm Gear in Ghaziabad ID Best Bronze For Gears Web per alloy is usually the best choice. Web manganese bronze, the strongest of the “as cast” bronze, is used primarily for heavy duty mechanical products. Web the bronze alloy of choice for worm gears is c90700 (sae65) high tin bronze. The three most common copper alloys used in gearing are brass, phosphor bronze, and. This has been the predominant.. Best Bronze For Gears.

From www.indiamart.com

MTE Mild Steel,Bronze Gears, For Industrial at best price in Khatauli Best Bronze For Gears Web the bronze alloy of choice for worm gears is c90700 (sae65) high tin bronze. Bronze gears are used in gear reducers. Web manganese bronze, the strongest of the “as cast” bronze, is used primarily for heavy duty mechanical products. This has been the predominant. For mating worms, iron metals such as s45c/scm44/scm415 are. Web per alloy is usually the. Best Bronze For Gears.

From www.nationalbronze.com

High Tin Bronze Alloys for Gear Applications National Bronze Best Bronze For Gears This has been the predominant. Web aluminum bronze is also popular for gears, bearings, and structural components due to its outstanding. The three most common copper alloys used in gearing are brass, phosphor bronze, and. Web per alloy is usually the best choice. Web copper alloy (bronze) gears have unique properties that contribute to minimal wear in bronze to steel. Best Bronze For Gears.

From www.indiamart.com

Heavy Vehicle Polished Gunmetal Bronze Gear, For Industrial at Rs 250 Best Bronze For Gears For mating worms, iron metals such as s45c/scm44/scm415 are. Web the bronze alloy of choice for worm gears is c90700 (sae65) high tin bronze. This has been the predominant. The three most common copper alloys used in gearing are brass, phosphor bronze, and. Adding tin to copper makes the alloy hard by replacing some copper. Web aluminum bronze is also. Best Bronze For Gears.

From hiconsumption.com

15 Best Bronze Watches of 2022 HiConsumption Best Bronze For Gears Web the bronze alloy of choice for worm gears is c90700 (sae65) high tin bronze. Adding tin to copper makes the alloy hard by replacing some copper. For mating worms, iron metals such as s45c/scm44/scm415 are. This has been the predominant. Bronze gears are used in gear reducers. Web aluminum bronze is also popular for gears, bearings, and structural components. Best Bronze For Gears.

From www.geartechnology.com

The New Age of Bronze Gear Technology Magazine Best Bronze For Gears This has been the predominant. Adding tin to copper makes the alloy hard by replacing some copper. Web per alloy is usually the best choice. Web manganese bronze, the strongest of the “as cast” bronze, is used primarily for heavy duty mechanical products. Web aluminum bronze is also popular for gears, bearings, and structural components due to its outstanding. Web. Best Bronze For Gears.

From www.indiamart.com

Bronze Gears Bronze Worm Gear Manufacturer from Ghaziabad Best Bronze For Gears Web per alloy is usually the best choice. Web copper alloy (bronze) gears have unique properties that contribute to minimal wear in bronze to steel contact. The three most common copper alloys used in gearing are brass, phosphor bronze, and. Bronze gears are used in gear reducers. For mating worms, iron metals such as s45c/scm44/scm415 are. Web the bronze alloy. Best Bronze For Gears.

From www.redmooncosplaysolutions.com

Aged Bronze Gears Best Bronze For Gears For mating worms, iron metals such as s45c/scm44/scm415 are. Bronze gears are used in gear reducers. Web aluminum bronze is also popular for gears, bearings, and structural components due to its outstanding. Web manganese bronze, the strongest of the “as cast” bronze, is used primarily for heavy duty mechanical products. Adding tin to copper makes the alloy hard by replacing. Best Bronze For Gears.

From www.indiamart.com

Light Vehicle Bronze Gears, For Machinery at Rs 1000/piece in Sas Nagar Best Bronze For Gears Adding tin to copper makes the alloy hard by replacing some copper. Bronze gears are used in gear reducers. Web manganese bronze, the strongest of the “as cast” bronze, is used primarily for heavy duty mechanical products. Web copper alloy (bronze) gears have unique properties that contribute to minimal wear in bronze to steel contact. The three most common copper. Best Bronze For Gears.

From www.athome.com

Bronze Industrial Gears Wall Decor 10 x 20in At Home Best Bronze For Gears Web copper alloy (bronze) gears have unique properties that contribute to minimal wear in bronze to steel contact. For mating worms, iron metals such as s45c/scm44/scm415 are. Web manganese bronze, the strongest of the “as cast” bronze, is used primarily for heavy duty mechanical products. Adding tin to copper makes the alloy hard by replacing some copper. Web per alloy. Best Bronze For Gears.

From designaholicstudio.com

Bronze Gears Embellishments Designaholic Studio Art Supplies Best Bronze For Gears Web manganese bronze, the strongest of the “as cast” bronze, is used primarily for heavy duty mechanical products. The three most common copper alloys used in gearing are brass, phosphor bronze, and. Bronze gears are used in gear reducers. This has been the predominant. Web per alloy is usually the best choice. Web aluminum bronze is also popular for gears,. Best Bronze For Gears.

From www.metaltek.com

Material Applications Wear Resistant Alloy Comparison MetalTek Best Bronze For Gears Adding tin to copper makes the alloy hard by replacing some copper. Web manganese bronze, the strongest of the “as cast” bronze, is used primarily for heavy duty mechanical products. Web the bronze alloy of choice for worm gears is c90700 (sae65) high tin bronze. Web aluminum bronze is also popular for gears, bearings, and structural components due to its. Best Bronze For Gears.

From www.youtube.com

Making a bronze gear YouTube Best Bronze For Gears Web copper alloy (bronze) gears have unique properties that contribute to minimal wear in bronze to steel contact. For mating worms, iron metals such as s45c/scm44/scm415 are. Web aluminum bronze is also popular for gears, bearings, and structural components due to its outstanding. Bronze gears are used in gear reducers. Web the bronze alloy of choice for worm gears is. Best Bronze For Gears.

From yushi.co.th

AluminumBronze Screw Gears บริษัท ยูชิ กรุ๊ป จำกัด Best Bronze For Gears The three most common copper alloys used in gearing are brass, phosphor bronze, and. Bronze gears are used in gear reducers. For mating worms, iron metals such as s45c/scm44/scm415 are. Web aluminum bronze is also popular for gears, bearings, and structural components due to its outstanding. Web the bronze alloy of choice for worm gears is c90700 (sae65) high tin. Best Bronze For Gears.

From pva.supply

Bronze Gears 23 Pattern Crew Best Bronze For Gears Bronze gears are used in gear reducers. This has been the predominant. Web the bronze alloy of choice for worm gears is c90700 (sae65) high tin bronze. Adding tin to copper makes the alloy hard by replacing some copper. Web manganese bronze, the strongest of the “as cast” bronze, is used primarily for heavy duty mechanical products. Web per alloy. Best Bronze For Gears.